Design Constraints

Each design trial solution is analyzed by a number of hydraulic simulation runs corresponding to the multiple demand conditions. The system responses, such as junction pressures, flow velocities, and hydraulic gradients, will be checked against the design criteria you set.

Pipe-Size Constraint

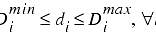

A list of available pipe sizes (and costs) is specified and used as a commonly shared data by all the pipe groups. For each group, you specify the minimum and maximum diameters, which narrows the scope of the optimization problem. Pipe size is selected from a list of commercially available pipe diameters within the range of the minimum and maximum limit, such as:

A set of pipe diameters can also be introduced to exclude the unfavorable pipe sizes to a pipe group. This set can be noted as:

Junction-Pressure Constraint

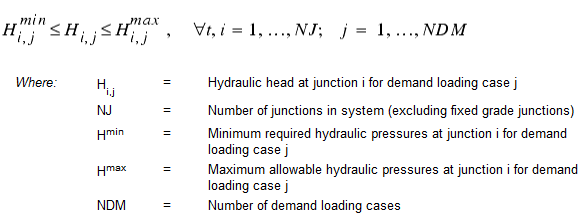

Junction pressure is often required to maintain greater than a minimum pressure level to ensure adequate water service, and less than a maximum pressure level to reduce water leakage in a system. Thus junction pressure constraints are given as:

Pipe Flow Constraint

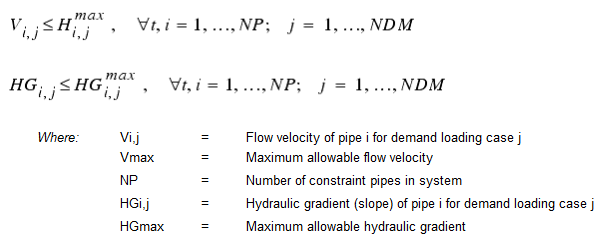

A design and rehabilitation solution is also constrained by a set of pipe flow criteria that are often given as a maximum allowable flow velocity and a maximum allowable hydraulic gradient or slope, given as:

In many system improvement designs, a feasible design solution must ensure the storage tank to be refilled to a certain water level so that a stable periodical supply can be established. To meet a tank refilling criteria, pipe flow velocity must be greater than the minimum required velocity, given as:

Budget Constraint

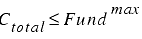

Water utilities are often constrained by a budget for a new subdivision design and/or the rehabilitation of an existing water system. When the optimization is conducted to maximize the value or benefit of the design, the optimal solution will be constrained by the available funding.